Throughout its history, Toyota has been at the forefront of electrification, boasting the first Prius hybrid as a testament to its expertise. However, as the world rapidly embraces the electric vehicle revolution, Toyota acknowledges the need for a great leap forward to meet the demands of the future. Their commitment goes beyond just developing cutting-edge electric vehicles; they are determined to revolutionize the manufacturing process itself. These innovative methods may be shared with its partners, fostering collaboration to drive scale and cut costs—a move that could shape the future of electric mobility.

Join us on this exciting journey as we uncover Toyota’s push into next-generation EVs and its potential to reshape the landscape of electric vehicles. As the world awaits the dawn of a new automotive era, let’s explore the innovations and strategies that Toyota brings to the table, striving for a greener, more sustainable future.

Toyota’s examination of the Tesla Model Y’s teardown results had a profound impact, revealing not just the technological secrets of the American electric crossover but also shattering the complacency within the Japanese automaker. Under the Model Y’s exterior, Toyota engineers discovered a remarkably simple yet ingeniously crafted vehicle structure, showcasing advanced manufacturing capabilities that left them in awe and admiration.Throughout its history, Toyota has been at the forefront of electrification, boasting the first Prius hybrid as a testament to its expertise.

However, as the world rapidly embraces the electric vehicle revolution, Toyota acknowledges the need for a great leap forward to meet the demands of the future. Their commitment goes beyond just developing cutting-edge electric vehicles; they are determined to revolutionize the manufacturing process itself. These innovative methods may be shared with its partners, fostering collaboration to drive scale and cut costs—a move that could shape the future of electric mobility.

Join us on this exciting journey as we uncover Toyota’s push into next-generation EVs and its potential to reshape the landscape of electric vehicles. As the world awaits the dawn of a new automotive era, let’s explore the innovations and strategies that Toyota brings to the table, striving this grudging adoration, however, also brought about a frightening revelation for Toyota, the largest carmaker in the world with a long history of electrification going back to the groundbreaking Prius hybrid in 1997. They recognized that to compete in the new era of fully electric vehicles, they must take a significant leap forward.

To address this challenge, Toyota is embracing an “EV-first” mindset, propelling them to work faster and more agilely than ever before. This shift also necessitates reevaluating their design-for-manufacturing processes, which have long been renowned for efficiency through the Toyota Production System.

Tesla’s revolutionary use of giga casting has redefined vehicle construction, consolidating the front and back sections into two massive modules, effectively eliminating countless parts and brackets. Furthermore, their innovative battery layout acts as a structural component, serving as the floor itself instead of being placed between the axles in a frame.

Tesla’s approach has led to the elimination of hundreds of parts and up to 220 pounds of weight while simultaneously improving the vehicle’s battery range and reducing overall costs. Toyota executives acknowledge that Tesla’s manufacturing philosophy is fundamentally distinct and necessitates the development of an entirely new platform, purpose-built for electric vehicles.

Startups like Tesla have a significant advantage due to their fresh perspective, which allows them to reimagine engineering challenges from the ground up. Tesla’s approach to powertrain cooling hoses exemplifies this, using thinner and more cost-effective materials due to the unique cooling requirements of electric vehicles. Consequently, significant cost savings and weight reductions, amounting to at least $25 and 11 pounds per vehicle, have been achieved.

Under the guidance of incoming CEO Koji Sato, a new leadership team is already at work, developing a wholly re-engineered, next-generation platform dedicated solely to battery electric vehicles, slated to arrive in 2026. This bold gambit marks Toyota’s commitment to carving a formidable path in the rapidly evolving electric vehicle landscape.

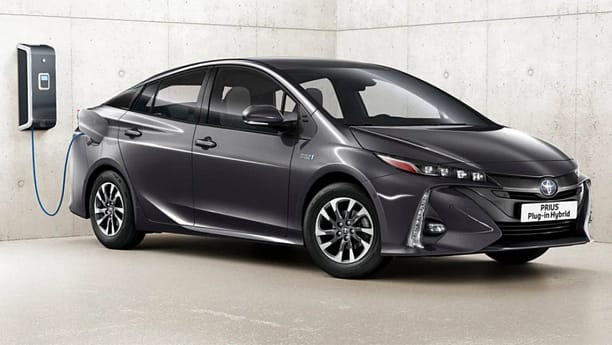

Sato, a seasoned engineer responsible for both the Lexus premium division and Toyota’s Gazoo Racing motorsports arm, has assured that Toyota will remain committed to Toyoda’s diversified powertrain strategy. In addition to pursuing electric vehicles, the company will continue producing its signature hybrid, plug-in hybrid, and hydrogen-powered cars.

As an example, the Lexus brand has already set a target to achieve full electrification worldwide by 2035, intending to sell 1 million EVs globally by 2030. For the entire Toyota organization, the aim is to achieve global sales of 3.5 million EVs within that timeframe. However, reaching these ambitious goals will require a rapid and substantial increase in EV sales. In 2022, Toyota’s fully electric vehicle sales were relatively modest at 24,466 units worldwide, compared to a much larger figure of 2.60 million hybrids sold during the same period.

Sato emphasized their clear vision for the type of battery electric vehicles (BEVs) they intend to produce. They plan to develop next-generation BEVs for the Lexus brand by 2026, optimizing everything from the battery and platform to the vehicle’s construction exclusively for BEVs. Simultaneously, they will expand their existing BEV lineup to cover a broader range of options.

Toyota also needs to address significant challenges, as exemplified by the situation in California. Traditionally, the automaker has held a strong position in the state’s eco-friendly market, with its reliable Camry sedan reigning as the bestselling passenger vehicle for an extended period. However, a shift occurred when the Tesla Model 3 emerged as the top-selling car in California last year, dethroning the Camry. Additionally, for two consecutive years, the Tesla Model Y surpassed Toyota’s RAV4 to become the leading crossover in the state.

Analysts predict that at its current pace, Tesla could potentially surpass Toyota as the state’s best-selling brand within a short span of one or two years. This development highlights the intensified competition Toyota faces from Tesla in the California market and underscores the urgency for the automaker to adapt and innovate to maintain its position.

Nevertheless, Toyota’s ambitious transformation towards electric vehicles promises a wide array of advantageous outcomes that extend far beyond the introduction of next-generation EVs designed to rival Tesla’s offerings, scheduled to commence production in 2026. The company’s radical shift includes implementing groundbreaking manufacturing processes, which will not only be applied to factories producing conventional vehicles but might also be shared with partner automakers. This collaboration seeks to bolster Toyota’s scale and significantly reduce costs.

Moreover, the impact of Toyota’s electric vehicle transition will extend to all facets of its global operations, not just its expanding EV business. Executives at the world’s largest automaker presented these multiplier effects during their recent briefing, detailing their intent to surge ahead in the global electric vehicle competition within a remarkably short timeframe.

Toyota is charting an innovative road map that involves comprehensive engineering changes for both its products and manufacturing processes. On the manufacturing front, the company aims to streamline its production procedures, reducing them by half and halving the amount of plant investment and production lead time. In terms of product development, Toyota plans to introduce a new EV platform, a cutting-edge software operating system, and a series of advanced batteries that could potentially enable EVs to achieve impressive driving ranges of up to 930 miles.

But Toyota recognizes that the advantages of these groundbreaking technologies extend beyond just BEVs. According to BEV Factory President Takero Kato, these innovative tools will lead to broader gains for the company, positively impacting quality and flexibility across all manufacturing and production activities. By adopting this approach, Toyota aims to enhance its overall performance and remain at the forefront of the automotive industry’s transformation.

Toyota is also set to introduce groundbreaking techniques like giga casting and self-propelled production, revolutionizing assembly plants with flexible, dynamic systems. These innovations, initially developed for EV factories, have the potential to extend to non-EV facilities as well, allowing Toyota to prioritize efficient manufacturing. The company aims to leverage digital twin technology by creating virtual replicas of production lines to expedite design, testing, and verification processes. These modern manufacturing methods not only enhance factory efficiency but also address an impending labor shortage caused by Japan’s aging and shrinking population. By reducing its reliance on human labor, Toyota plans to reassign redundant workers to higher-value roles within the organization.

The adoption of revamped production techniques is vital for Toyota’s cost-cutting efforts with its next-generation EVs. The company envisions engineering new vehicles from scratch, focusing on hyper-efficient manufacturing techniques, and seeking additional revenue streams from services.

Toyota has the potential to boost both sales volume and profit margins by sharing its new EV technologies with other companies in its alliance. The carmaker leads an alliance of car manufacturers interconnected through cross-shareholdings, which includes Subaru, Mazda, Suzuki, Daihatsu, Hino, and Isuzu. When considering their combined global sales, this alliance forms a formidable Japanese force, selling a total of 16.3 million units.

In the past fiscal year that ended on March 31, Toyota, along with Daihatsu and Hino, achieved retail sales of 10.56 million vehicles worldwide. Subaru sold 852,000 vehicles, Mazda moved 1.11 million, Suzuki contributed another 3 million, and Isuzu added 771,000 trucks to the alliance’s sales.

Toyota is already taking steps to share costs and increase volume with Subaru, as they have collaborated on the bZ4X, which Subaru sells as the Solterra. Additionally, Toyota is committed to supplying its hybrid drivetrains for Subaru’s lineup of next-generation hybrids.

Chief Technology Officer Nakajima is eager to expand these collaborative partnerships for mutual supply. If Toyota gains confidence in its innovative ideas, the company aims to open up its technologies to help other companies achieve their carbon neutrality goals. This approach aligns with Toyota’s broader vision of fostering a collective effort toward a more sustainable future for the automotive industry.